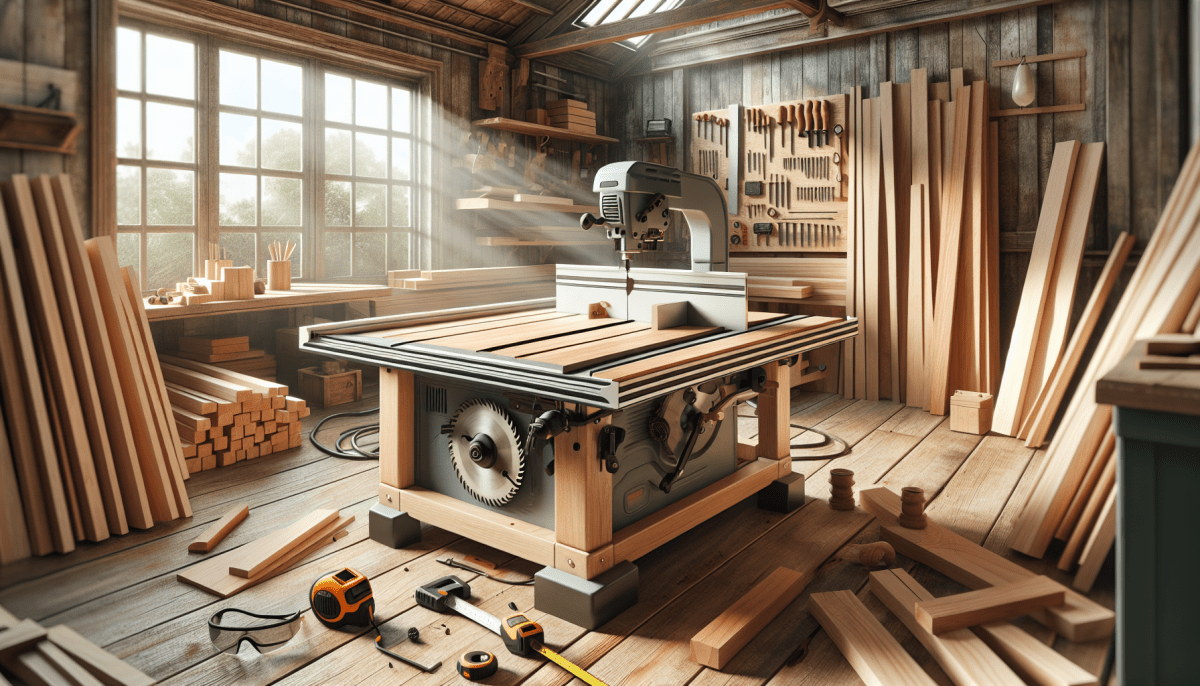

Understanding the basics of a table saw is essential for anyone looking to enhance their woodworking skills. A table saw is a powerful tool that allows you to make precise cuts with ease. At its core, it consists of a flat table surface where the wood rests, a blade that protrudes from the table, and a motor that drives the blade. This setup offers remarkable versatility, enabling you to make rip cuts, crosscuts, and even angled cuts with the right adjustments.

One important feature of the table saw is the blade height adjustment. By raising or lowering the blade, you can control how deep the cut will be. It's vital to match the blade height to the thickness of the material you are working with. Additionally, the table saw often comes with a fence, which helps in guiding the wood during cuts, ensuring straight, accurate results. Understanding how to properly set the fence and adjust the blade height will significantly improve the quality of your work.

Safety is another crucial aspect to consider when using a table saw. Always make sure to use push sticks or paddles for smaller pieces of wood, maintaining a safe distance from the blade. Wearing safety goggles and ear protection is also advisable since the saw can create flying debris and produce significant noise. Familiarizing yourself with the emergency stop features and the saw’s off switch will give you added peace of mind during operation.

Lastly, regular maintenance of your table saw can greatly extend its life and performance. Keep the blade sharp and clean, and ensure the table surface is free of dust and debris. A well-maintained table saw not only runs more efficiently but also delivers more accurate cuts, allowing you to achieve better results in your woodworking projects. By grasping these basic concepts of table saw operation, you’ll be well on your way to mastering this essential tool in your woodworking arsenal.

Choosing the Right Table Saw

First, determine the type of table saw you need. There are three main categories: contractor saws, cabinet saws, and portable saws. Contractor saws are great for those who need a balance of power and portability. They are typically less expensive and ideal for beginners or hobbyists. If you are a serious woodworker, consider a cabinet saw. These saws offer more stability and precision, making them suitable for professional-grade work. On the other hand, if you're looking for something easy to transport for on-site projects, a portable saw would be the right choice.

Next, think about the size of the table saw and the space you have available. A larger saw can provide more cutting capacity, which is helpful for tackling bigger pieces of wood. However, if your workshop is on the smaller side, a compact model might be more practical. It's also essential to check the fence system and ensure it's reliable. A good fence helps you achieve accurate cuts every time, so investing in a system that locks securely in place is crucial.

Another factor to consider is your budget. While it can be tempting to go for the cheapest option, remember that quality matters. A well-made table saw can last for years and save you money in the long run. Look for saws that offer good warranties and customer support. Finally, read reviews and seek recommendations from experienced woodworkers to ensure you're making an informed decision.

Essential Safety Tips for Table Saws

When working with table saws, safety should always be your top priority. It’s essential to familiarize yourself with the machine and its components. Always start by reading the manufacturer's manual to understand the specific features and safety mechanisms of your saw. This knowledge will help you operate the tool correctly and minimize risks.

Always wear appropriate personal protective equipment (PPE) when using a table saw. This includes safety glasses to protect your eyes from flying debris, hearing protection to guard against loud noises, and a dust mask to keep harmful particles out of your lungs. Additionally, consider wearing non-slip shoes and work gloves designed for high grip without sacrificing dexterity.

Before making any cuts, ensure that the blade is sharp and properly aligned. A dull blade forces you to apply unnecessary pressure, which can lead to accidents. Always use the saw's safety features, such as blade guards and riving knives, to prevent kickback. If you need to make adjustments or change the blade, unplug the saw or turn off the circuit breaker to avoid accidental start-ups.

Maintain a clutter-free workspace to reduce the risk of injury. Keep your hands away from the blade by using push sticks or other aids, especially when making narrow cuts. Never reach over the blade while it is running, and always stand to the side of the saw to protect yourself in case of kickback. Following these safety tips can help ensure a safer woodworking experience.

Advanced Techniques for Woodworking Projects

When it comes to woodworking, mastering advanced techniques can significantly elevate the quality of your projects. One of the most useful skills in this area is the ability to make precise cuts using your table saw. Techniques such as the use of jigs and fixtures allow woodworkers to create repeatable cuts, ensuring that every piece fits together flawlessly. Whether you’re crafting furniture or cabinetry, understanding how to set up and utilize jigs efficiently will save you time and improve your accuracy.

Another important advanced technique is the art of bevel cutting. Bevel cuts can add a unique touch to your projects, enabling you to create more intricate designs. With a table saw, you can tilt the blade to achieve the perfect bevel angle. It's essential to practice on scrap pieces before tackling your actual project, as this will help you become comfortable with adjusting the blade and maintaining consistent angles. Additionally, using a miter gauge for bevel cuts can further enhance your precision.

For those looking to take their woodworking skills a step further, mastering the technique of dados and grooves is invaluable. Whether you're fitting shelves into a cabinet or adding decorative elements to your woodworking projects, knowing how to cut precise grooves can transform your work. By using a dado blade set or multiple passes with your table saw, you can create these joints cleanly and effectively. Understanding the thickness of your materials and making the necessary calculations is key to achieving a perfect fit.

Lastly, don't underestimate the power of finishing techniques. After cutting and assembling your pieces, the final look is largely determined by how you finish the wood. Techniques such as sanding, staining, and sealing can enhance the grain and protect the wood from wear. Experimenting with various finishes will help you discover what works best for your particular projects. Remember, attention to detail in your finishing process can make even the simplest projects shine.