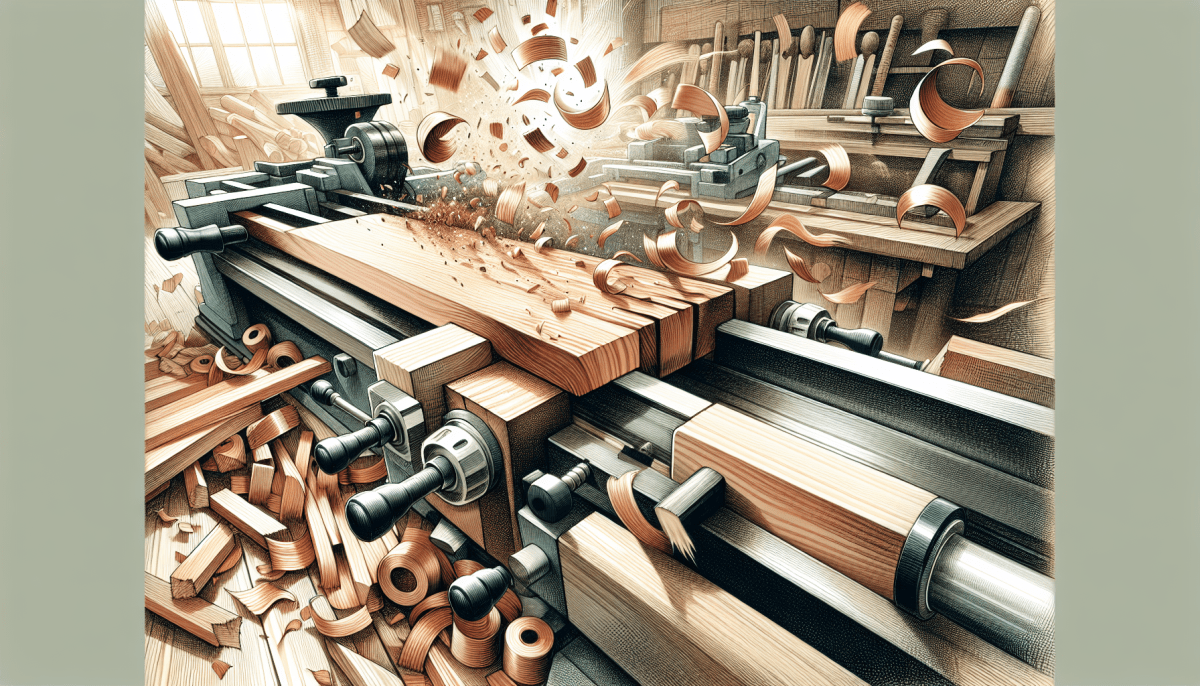

Jointers are essential tools in the woodworking shop, designed to create flat surfaces on lumber. When working with rough-sawn wood, the first step is often to remove any imperfections and ensure that one edge is perfectly straight. This is where a jointer shines. It is equipped with sharp knives that shave off thin layers of wood, allowing you to achieve a smooth, level surface that is ready for further processing.

The primary purpose of a jointer is to flatten one face and one edge of a board. By placing the rough side down and running the board through the machine, you can eliminate cups, twists, and dips. After achieving a flat surface, you can then use the jointer to create a square edge, which is crucial for making precise cuts with a table saw or other equipment. These steps ensure that your pieces fit together seamlessly, which is particularly important for projects like tabletops or cabinetry.

Jointers come in various sizes and configurations, making them adaptable for different workshop setups and project needs. Some models are small, portable units that might suit hobbyists, while larger industrial models can handle thicker materials and heavier use. Regardless of size, all jointers perform the same fundamental tasks: they level wood surfaces and create straight edges, making them indispensable for any serious woodworker looking to master the craft.

In addition to their flatness and squareness capabilities, jointers also contribute to the overall quality of your woodworking. By ensuring that your boards are even and well-prepared, you set yourself up for success in the assembly and finishing stages. A well-jointed edge can greatly improve the appearance of joints and seams, resulting in a more professional-looking final product. Understanding how to effectively use a jointer can elevate your woodworking skills and lead to flawless outcomes in your projects.

Key Features of Top Jointers

When it comes to achieving flawless edges in woodworking, a quality jointer is essential. Top jointers come equipped with several key features that significantly enhance their performance. Understanding these features can help you choose the right jointer for your woodworking projects.

One of the standout characteristics of leading jointers is their cutting width. Most premium jointers offer a cutting width ranging from 6 to 12 inches, allowing woodworkers to flatten wider boards with ease. A broader cutting capacity means fewer passes to achieve a smooth surface, saving you time and effort in the workshop.

Another crucial feature is the bed length. Longer beds provide better stability and support for your wood, reducing the likelihood of snipe, which is the unwanted tapering at the ends of a board. A jointer with a bed length of 60 inches or more is particularly advantageous for professionals who work with large stock, as it ensures consistent results.

Dust collection systems are also a vital aspect of top jointers. Effective dust collection reduces mess and keeps your workspace clean, while also improving visibility as you work. Many high-end models come with integrated dust ports that connect to your shop vacuum, making post-project cleanup much simpler.

Finally, the quality of the cutter head plays a significant role in the jointer’s performance. High-speed steel blades or helical cutter heads offer superior cutting efficiency and provide smoother finishes. Helical cutter heads are especially preferred for their quieter operation and reduced tear-out, making them an excellent choice for precision woodworking.

Proper Techniques for Using Jointers

Using a jointer is crucial for achieving smooth, flat edges on your woodworking projects. To get the most out of your jointer, it’s important to follow some proper techniques. First and foremost, always check the alignment of the jointer's infeed and outfeed tables. They should be level with each other; an uneven surface can lead to inconsistent results and even damage to your workpiece.

Before starting, ensure your boards are free from any protruding knots, screws, or nails. These can wreak havoc on your jointer blades and produce rough surfaces. When feeding the wood through the jointer, apply even pressure on the edges while keeping the wood firmly against the fence. This helps maintain accuracy and prevents the wood from tipping or shifting as it passes through the cutter head.

As you work, take small passes rather than attempting to take off a large amount of material at once. This not only prolongs the life of your jointer's blades but also allows for more control over the shaping process. Aim for about 1/16 inch to 1/32 inch cuts, checking the surface frequently to ensure you’re reaching the desired flatness.

Another key technique is to make sure both the infeed and outfeed sides are clear of any debris before you start. Dust and wood shavings can lead to poor performance and safety hazards. Lastly, always keep your hands and fingers away from the cutter area. Use push blocks whenever possible to guide the wood safely, protecting yourself while ensuring precision in your joinery work.

Troubleshooting Common Jointers Issues

When working with jointers, it's not uncommon to run into some common issues that can affect the performance of your tool. Understanding these problems can save you time and frustration as you strive for those perfect, smooth edges. Here are a few troubleshooting tips to help you get back on track.

One of the most frequently encountered problems is the jointer's blades becoming dull or damaged. Dull blades can result in tearing the wood instead of producing a clean cut. If you notice this happening, it's crucial to check the blades and sharpen or replace them as necessary. Regular maintenance will go a long way in ensuring your jointer works efficiently.

Another issue that can arise is an improper alignment of the infeed and outfeed tables. If these surfaces are not level with one another, you might end up with uneven edges on your boards. To fix this, use a straightedge or level to check the alignment and make adjustments as needed. A properly aligned jointer is essential for achieving the flawless edges you desire.

Finally, issues with your jointer's feed speed can lead to problems as well. If the wood is fed too quickly, it may result in a rough finish. Conversely, feeding too slowly can cause the blades to dig into the wood. Aim for a steady and consistent feed rate to achieve that perfect cut. Practice makes perfect, so don’t be discouraged if it takes a few tries to get it just right!